- Pick Up -

The hats in question are made at Kyodo Hat Factory in Gifu Prefecture.

The company has a history of over 90 years since its founding, and its president, Ryuichi Miwa, is the fourth generation.

Craftsmen carefully manufacture a wide variety of hats using natural materials, including felt hats.

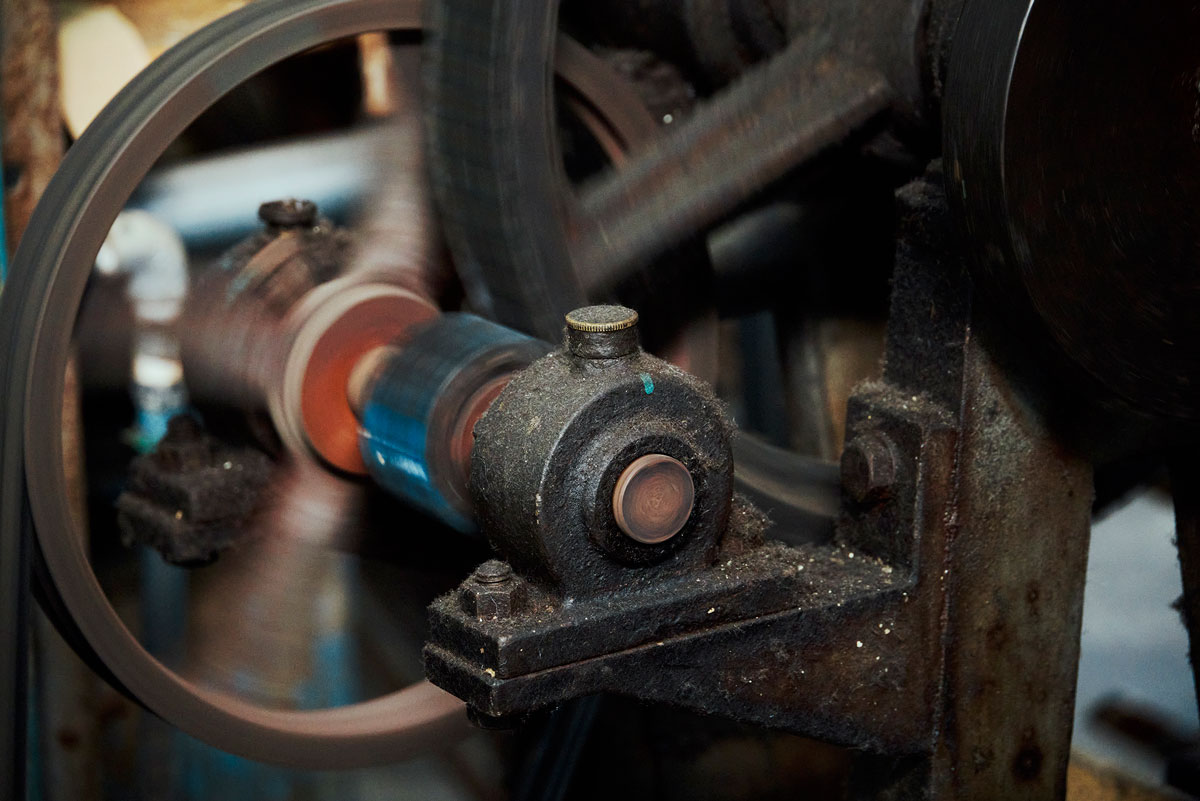

The pleasant sounds of machines operating in a steady rhythm echo throughout the factory, mixed with the breathing of the craftsmen.

"This was a capital investment that was only possible in those days. There are no other companies building a factory like this these days," said President Miwa.

The manufacturing method has remained unchanged since the early Showa period. The machines have been cherished for a long time. The craftsmanship has been passed down through the generations.

The passion of the people who make the hats and think about the people who wear them is certainly in the air.

- The Making -

STEP 1 Stretch

"The secret to beauty is the technique of spreading it evenly."

Felt is a non-woven fabric made by intertwining animal fibers such as wool and synthetic fibers into a sheet.

Felt is a non-woven fabric made by intertwining animal fibers such as wool and synthetic fibers into a sheet.

One of the characteristics of this fabric is that it stretches when heated and moistened and pulled.

The craftsman applies hot steam to the hat and stretches the crown and brim, creating the prototype of the hat.

"Should we make the brim 5cm or 8cm? Getting the tension just right is difficult. If we pull too hard, the fabric will have thick and thin areas, so we need to stretch it as evenly as possible," says President Miwa.

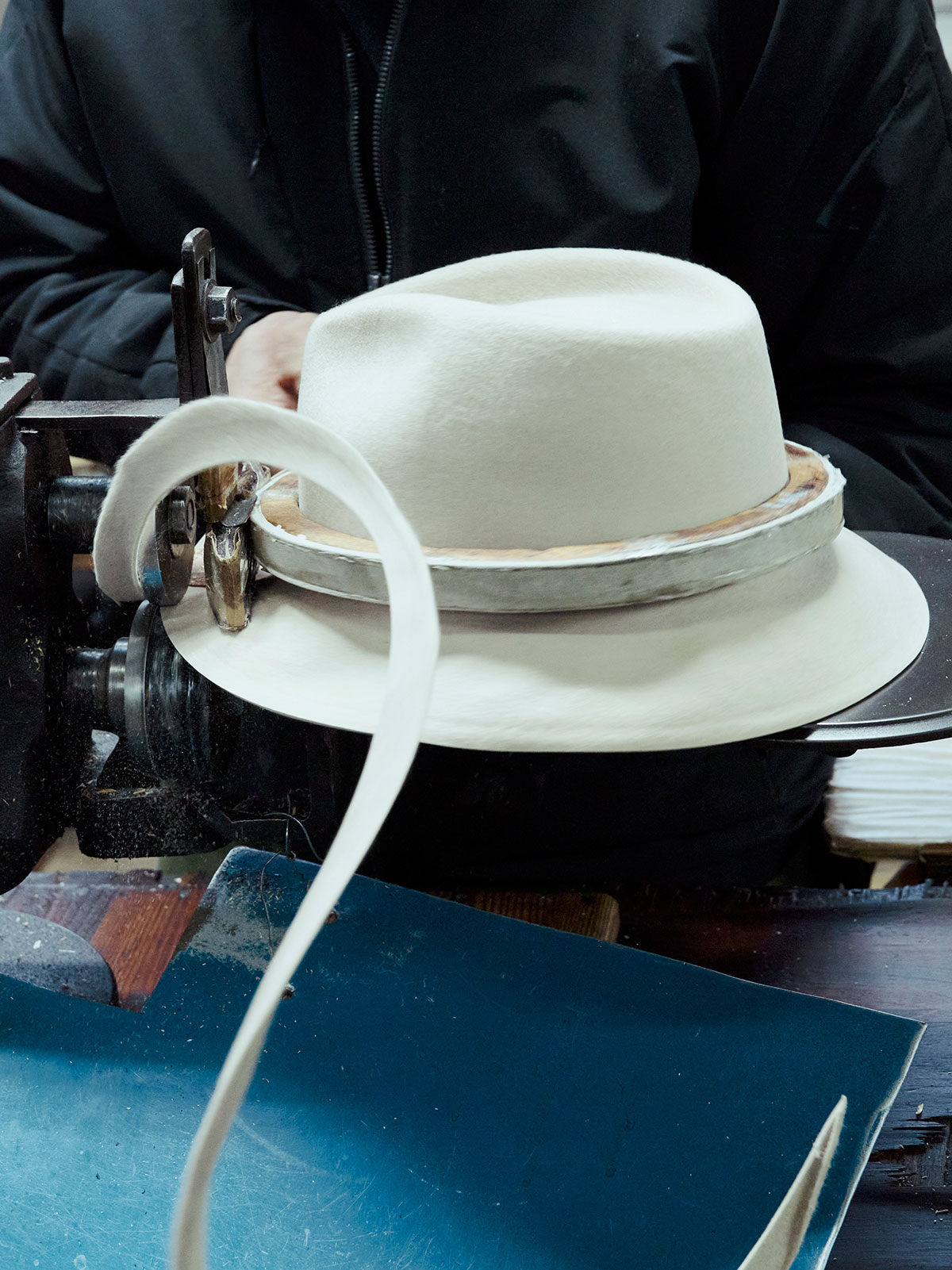

STEP 2: Harden

"Even after 40 years, I still get excited about new designs."

After softening and stretching the dough, it is hardened.

Once the wooden mold is placed into the hat, it is pressed using a special machine.

Temperature, pressure, time - with the artisan's exquisite control, the felt hardens towards the desired final shape.

"No matter how many years I've been doing this, I still get excited about new designs. By the way, the parts for this machine have been out of production for a long time. Whenever it breaks down, I go to a local factory and make a replacement part myself." (President Miwa)

STEP 3 Finishing

"Made in Japan means the mindset of creating products made with care"

The brim is cut according to the blueprint. The tip of the brim of the hat is rotated at high speed and cut off in an instant by the craftsman, but it is a tense job in which even the slightest deviation is not allowed.

We are particular about attaching ribbons by hand.

"When you use a sewing machine, the thread is always visible, about 1mm wide. Many mass-production factories overseas use sewing machines, but sewing with a needle and thread requires skilled hands. Even though it takes time and effort, we want to deliver a good product to the wearer... I think 'Made in Japan' means we are committed to making products that are made with care." (President Miwa)

Finally, a special oil mixture of olive oil and wax is applied to the surface to give it a glossy finish, and the piece is complete.